Pete Cook is a key member of the HTO Prostaff and the brains behind the HTO Artic Eel Shore and Vertical Lure. Here Pete runs through how he came up with the idea and shows us some of the steps he took to design and create this hugely successful lure.

The Idea

I can’t believe it’s been nearly 2 years since the idea first came about to produce our own lure for the UK lure market and beyond. Although my initial idea wasn’t even on the lines of an eel but more of a shad style body, the final design morphed into an eel.

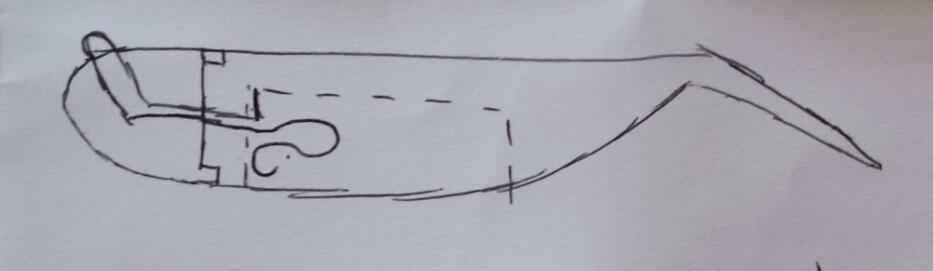

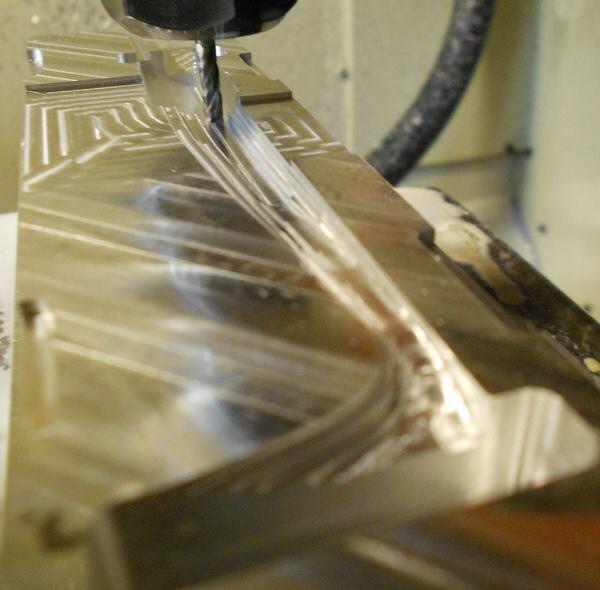

It all came about while I was teaching a friend, Jim, how to fish for bass at our local beach. After we had caught a few fish we sat down and started to look at some of the soft plastics I use and how to apply them to certain situations. I could see my friends brain working overtime to the point of him saying let’s make some of our own? Now I knew he was an engineer but didn’t realise he was a CNC machinist with endless capabilities. We had drawn a few ideas on paper which he then took away and produced some amazing moulds which replicated our previous drawings to the very finest of detail. After possibly 10 or so moulds we finally came up with the EEL.

Bringing it to life…

Now neither I nor Jim had ever poured our own plastic into moulds using liquid plastisol and I remember an evening at my mums business trying to get to grips with melting times, etc. The first fewpours were not successful to the point where I melted the jug in the microwave! It was funny at the time but I was pulling my hair out, so we made a late night visit to Tesco and invested in some proper Pyrex jugs which, to be honest, we should have used from the start. Now we could heat the plastic to the correct temperature and get it right into the mould.

Air bubbles and voids

Being a newbie at melting this plastisol and the moulds being so complex I honestly reckon it took us 4 or 5 evenings to actually pour our first decent body. The main problems were air pockets in the moulds which made voids on the tails so the moulds were reworked and more vent holes made to release all the air. This seemed to work ok but the end product again was not up to our fussy standard.

We had spent so many evenings doing this at various locations that it was getting to the point that we thought it wasn’t going to happen due to the complexity of the mould.

What we needed was an injection system to fire the liquid into the moulds under pressure to push out all the air. Lo and behold, the machinist went away again and made a set of injectors with dual spouts for different loads of liquid and this cured the problem.

Suddenly the idea was looking real. Every lure came out of the mould perfectly. The great thing about the home made injector was that the dual tubes enabled us to make the custom colours we wanted; it was honestly like being a kid in a sweet shop. We had moulds, injectors, the melt times of the plastic were spot on to get a consistent pour so all things were heading in the right direction. Happy days!

Heads and Hooks…….

This was a fairly simple part of the puzzle as we wanted a head shape for fishing vertically from the boat and deeper rock marks and a shape for the shore or casting from the boat.

After a few drawings and some discussion the head moulds were ready for pouring. Fortunately George (Tronix MD) had purchased a proper smelting pot which made this operation a breeze and soon we had both shore and vertical heads in 6 different weights and sizes to match the tails. I based the design around a certain hook pattern which fitted perfectly but was slightly on the thick side. In testing this was fine but it became apparent that this particular pattern would be hard to source. Fortunately, with a few adjustments to the mould, the new hook was in place, fitted perfectly and, most importantly, worked.

To find your nearest store stocking the HTO Artic Eel visit our Store Locator!